Quality Control System

Zero Defect Policy

We guarantee adherence to all standards for product quality control, utilizing integrated hardware and software solutions to maintain international quality benchmarks throughout manufacturing stages.

Production Capabilities

Comprehensive manufacturing solutions with rigorous quality control

High-Volume Die Casting

Up to 15,000 units/month via high-pressure die casting with consistent quality

Powder Metallurgy

300,000 units/month capacity with precision sintering processes

CNC Machining

Small batches and prototyping starting from 100 units with tight tolerances

Tooling Validation

100% tooling validation, material testing, and First Article Inspection (FAI)

Surface Finishing

Anodizing, powder coating, electroplating with quality verification

Welding Services

MIG, TIG, and laser welding with certified procedures

Three-Stage Inspection System

Systematic quality control at every production phase

Raw Material Verification

- Spectrochemical analysis of alloy composition

- Tensile/compression mechanical testing

- Dimensional inspection

- Supplier quality audits

- Material certification review

- Chemical composition testing

In-Process Monitoring

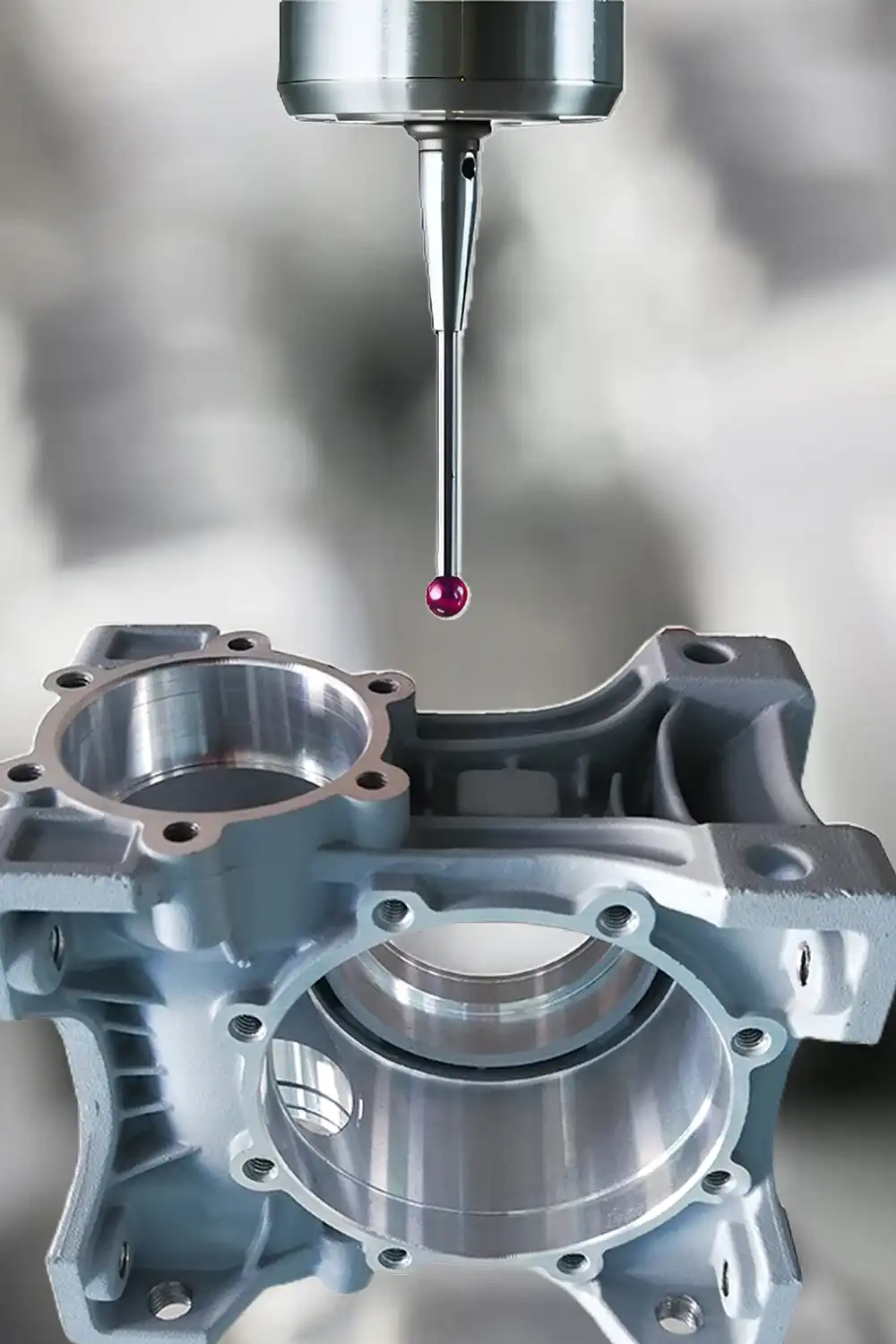

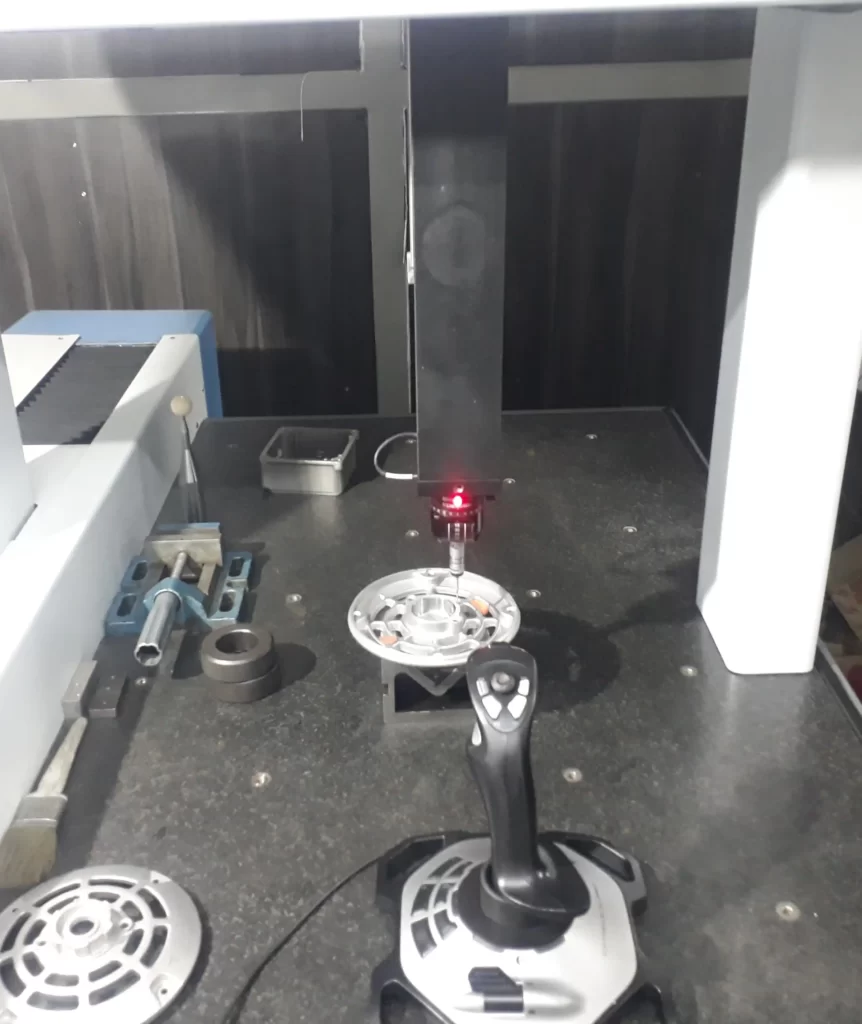

- CMM measurement with margin of error <3μm

- Quality checkpoints every 45 machine hours

- Real-time data monitoring systems

- Operator training in quality techniques

- Machine calibration protocols

- Statistical process control (SPC) charts

Final Acceptance Protocol

- Verification of 8 critical geometric parameters

- Fastener torque calibration

- Functional testing under operational conditions

- Documentation review for traceability

- Visual inspection for surface defects

- Packaging verification

Our Commitment

"We are 100% committed to our work so that our customers can be sure of the quality of their products. Systematic elimination of production deficiencies is our standard practice."

Quality Control Equipment

State-of-the-art testing and measurement technology

Advanced Testing Equipment

- Coordinate Measuring Machines (CMM) with <3μm precision

- Spectrochemical analyzers for material composition

- Tensile and compression testing equipment

- Surface roughness measurement systems

- Optical inspection and microscopy

- Hardness testing equipment

- X-ray inspection for internal defects

- Real-time SPC monitoring systems

Quality Control Laboratory

Precision Measurement

Certifications & Standards

International quality management certifications

Why Choose HydroForce?

Your trusted partner for precision manufacturing

- ISO 9001:2015 certified quality management system

- Advanced CMM and testing equipment with <3μm precision

- Full traceability throughout entire production process

- Continuous improvement and zero-defect culture

- Experienced quality control team

- Comprehensive documentation and certificates

Experience Our Quality Commitment

Contact us to learn more about our quality control processes and certifications

Get In Touch