Powder Metallurgy (PM) & Metal Injection Molding (MIM)

Precision, Strength, and Innovation for Your Business

Looking for a partner to manufacture high-quality metal components of any complexity? We are specialists in Powder Metallurgy and MIM technologies delivering exceptional results.

Our Advantages

Why choose Powder Metallurgy and MIM technologies

Cost Efficiency

- Minimal material waste — save up to 30% on raw materials

- High repeatability — reduces post-machining needs

- Complex shapes produced in one cycle — simplified assembly

Design Freedom

- Manufacture of highly complex parts impossible via conventional methods

- Lightweight yet strong components to boost product efficiency

- Near-net-shape manufacturing capabilities

Consistent Quality

- High mechanical strength and wear resistance

- Tight process control and multi-stage quality assurance

- Reliable performance in demanding applications

Who We Serve?

PM and MIM solutions across diverse sectors

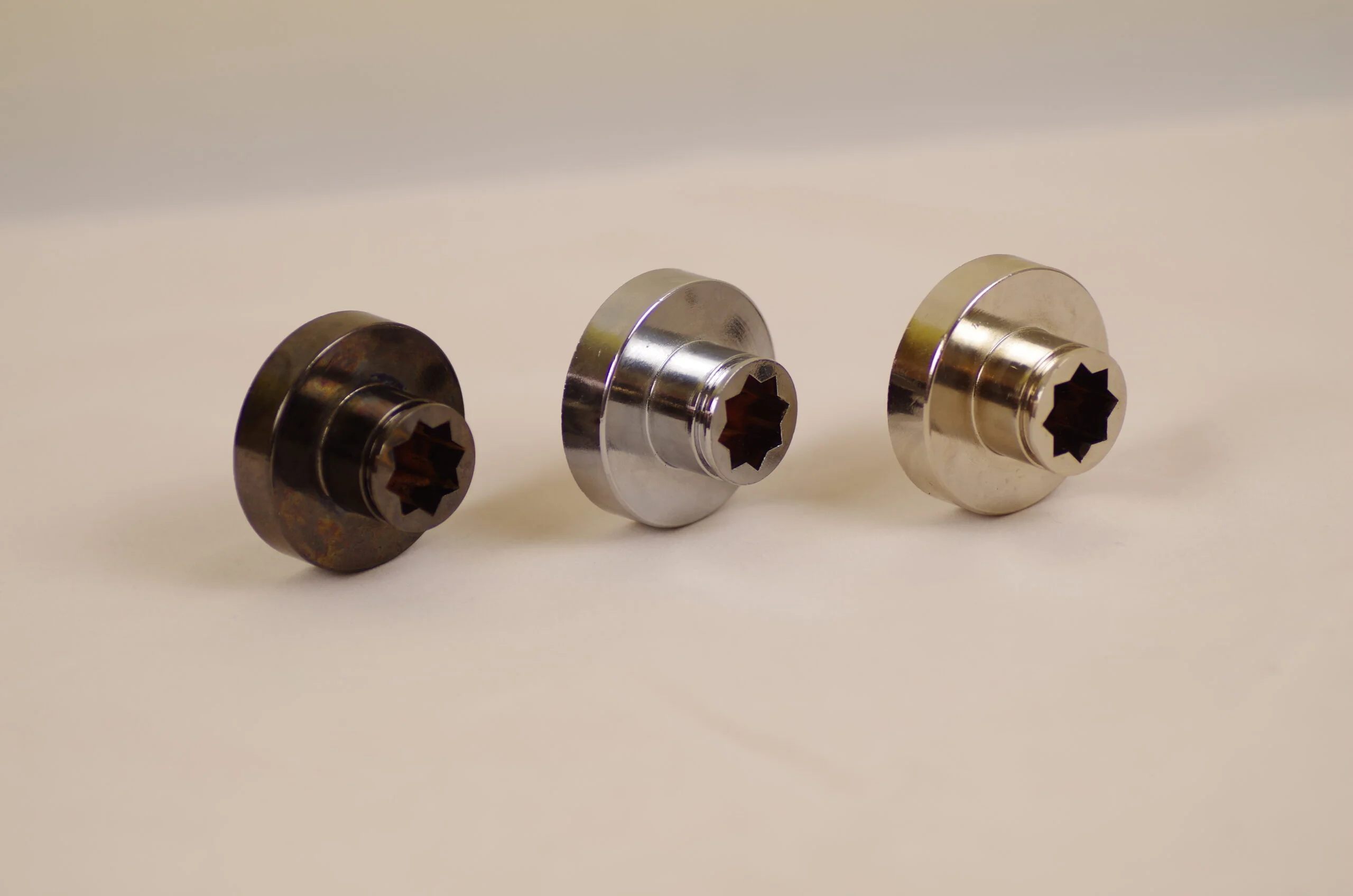

Automotive

Reliable, precision components

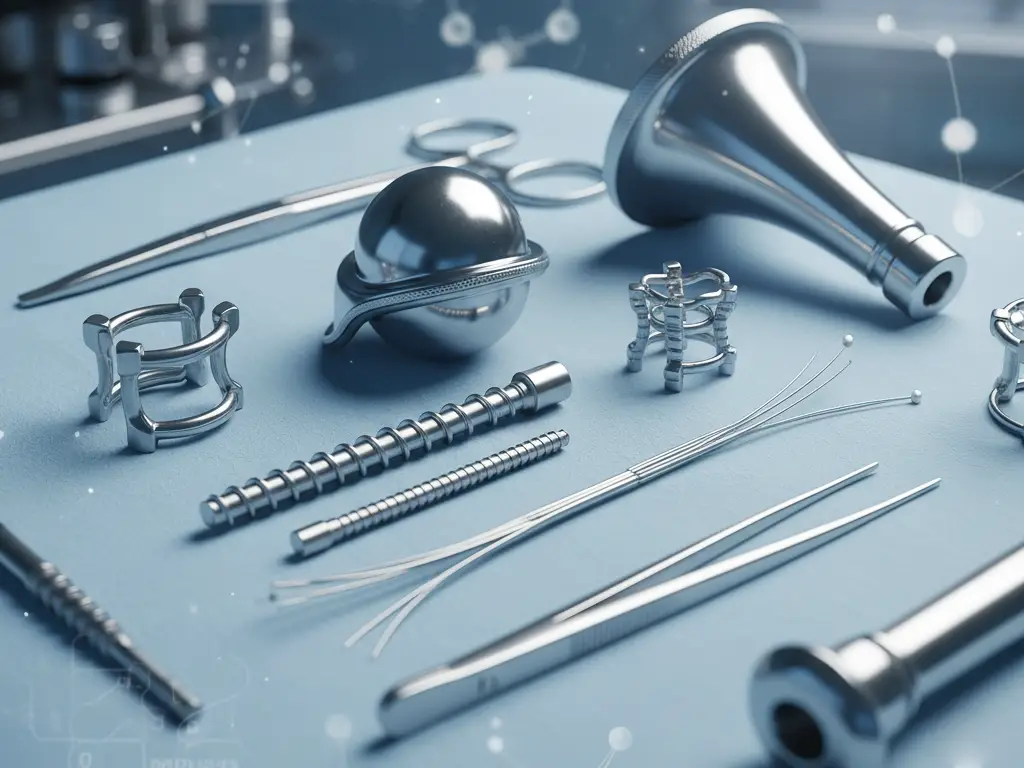

Medical

Biocompatible and long-lasting parts

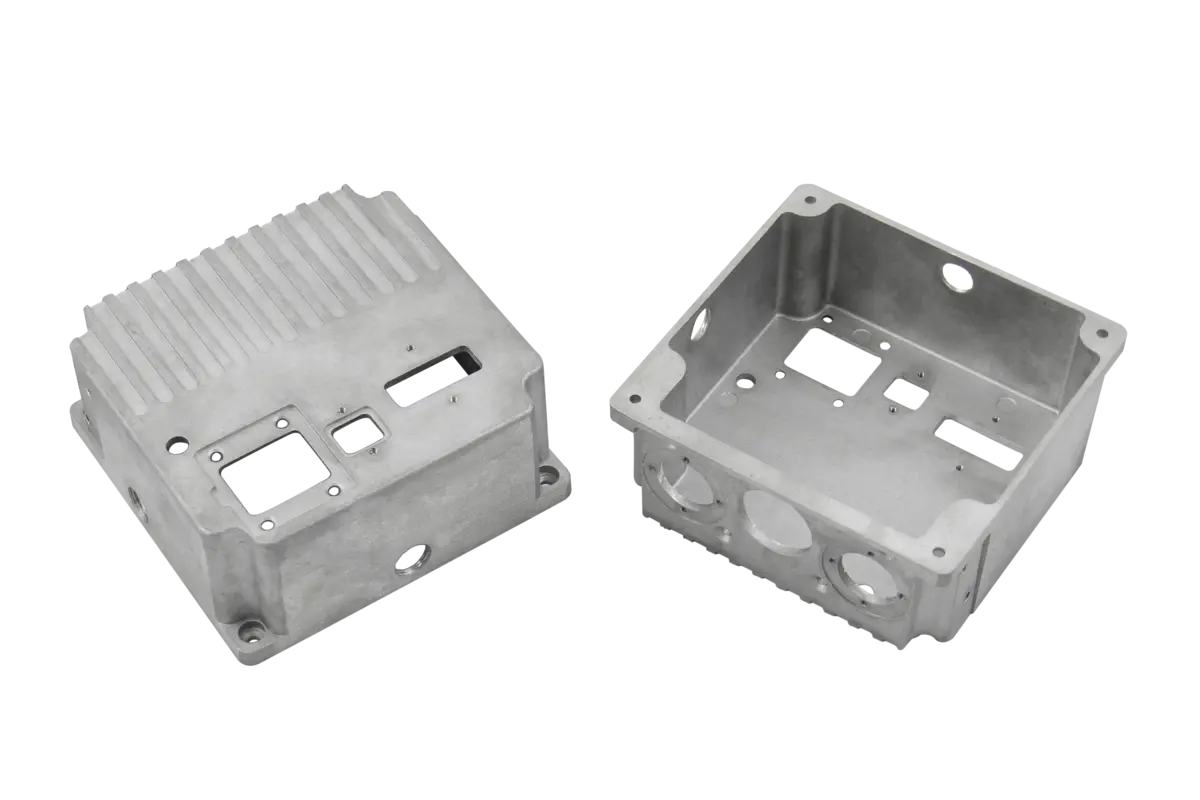

Electronics

Miniature components with complex geometries

Tooling & Equipment

High-strength wear-resistant parts

Conventional Powder Metallurgy (Sintering)

High-strength parts with tight tolerances

Materials

- Carbon and alloy steels

- Stainless steel

- Copper alloys

- Titanium

Specifications

- Sintering Temperature: 1100°C to 1400°C (±5°C precision)

- Atmosphere: Vacuum, inert gases (argon, nitrogen)

- Compaction: Up to 800 MPa, green density >95%

- Tolerances: ±0.05 mm after sintering

- Post-processing: CNC machining, heat treatment, surface hardening

- Quality Control: Metallographic analysis, hardness testing

High-strength parts with tight tolerances, optimized material usage and reduced finishing costs.

Precision Gears

Structural Parts

Complex Shapes

Metal Injection Molding (MIM)

Production of miniature, high-precision parts

Materials

- Ultra-fine metal powders (<20 μm)

- Specially formulated polymer binders

- Stainless steels and tool steels

- Titanium and superalloys

Specifications

- Feedstock: >97% final density achievable

- Injection Molding: Complex shapes with thin walls down to 0.3 mm

- Debinding: Thermal or chemical removal with stress control

- Sintering: Programmable furnaces with inert/vacuum atmospheres

- Tolerances: Standard ±0.02 mm, calibrated down to ±0.01 mm

- Surface Finish: Ra as low as 0.4 μm without additional finishing

Production of miniature, high-precision parts with minimal secondary operations.

Medical Components

Electronic Parts

Precision Parts

Combined PM & MIM Solutions

Integrated manufacturing for optimal results

- Integrated PM and MIM solutions for optimal manufacturing

- Process automation with real-time monitoring and control

- Eco-friendly production with low material waste and energy efficiency

- Engineering support for design adaptation and optimization

Manufacturing Process

Quality Control

Production Line

Why Choose HydroForce?

Your trusted partner for PM and MIM manufacturing

- 15+ years of experience in complex metal part manufacturing

- Advanced production facilities and in-house R&D

- Flexible order volumes — prototyping to full-scale production

- Full quality assurance and certifications

- Technical consulting and design optimization support

Feel Free to Contact Us

Let us help you find the optimal PM or MIM solution for your application

Request Quote