Machining

Manufacturing of Standard, High-Precision, and Large-Scale Components

We offer comprehensive machining services for standard, precision, and large components, including custom gears with modern equipment and strict quality control.

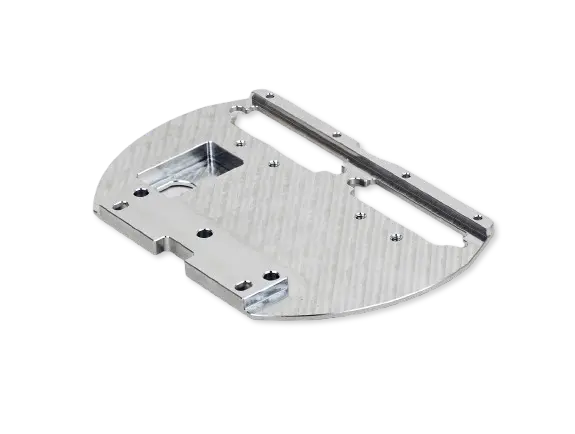

Standard Parts Production

Production of standard metal parts in series with typical sizes and tolerances using versatile machinery for efficient batch processing.

Typical Products

- Shafts and Axles

- Flanges

- Bushings

- Housings

- Brackets and Mounting Plates

- Covers and Caps

- Sleeves and Rings

- Machined Blanks

Equipment

- Haas CNC Milling Centers (1270 x 660 x 635 mm work envelope)

- DMG MORI Turning Machines (Ø500 mm diameter, 1000 mm length)

- Precision grinding, drilling, and boring machines

High-Precision Components

Series production with tight tolerances, form accuracy, and surface finish. Dimensional repeatability within IT6-IT7 and geometric control aligned with ISO 2768-fH, ISO 286, ISO 1101.

Typical Products

- Precision parts for hydraulic/pneumatic systems

- Bearing and seal seats

- Shafts with minimal runout

- Precision housings and flanges

Capabilities

- Haas CNC milling with thermal deformation compensation

- Renishaw probing system for in-process measurement

- DMG MORI CNC turning supporting H6/h6 precision fits

- IT6-IT7 tolerance range

- CMM inspection protocols

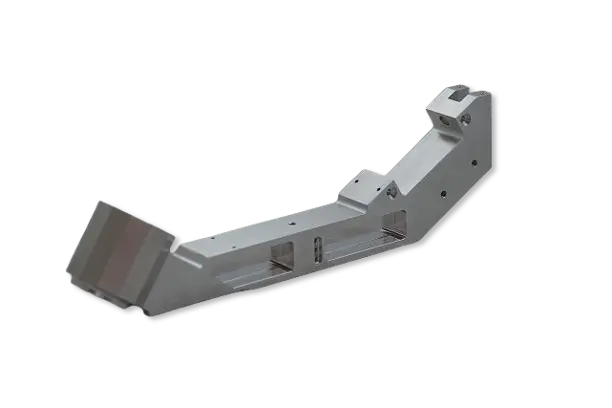

Large and Custom Components

Strategic focus area producing rods and shafts up to 2m diameter and 16m length, including custom hydraulic cylinder parts.

Typical Products

- Large-diameter rods and shafts

- Oversized flanges and housings

- Hydraulic cylinder bodies

- Major hydraulic assemblies

Equipment

- DMG MORI milling centers with extended work envelope

- Schiess lathes (2m diameter, 16m length capacity)

- Klingelnberg and Walter grinding and boring machines

- Specialized lifting and handling equipment

Industries Served

Precision machining solutions across diverse industrial sectors

Hydraulic & Industrial Machinery

Cylinder components, pump/valve housings, power transmission

Power Generation

Hydro turbine components, thermal plant parts, generator housings

Shipbuilding & Marine

Propeller shafts, engine components, deck machinery

Mining & Metallurgy

Crusher components, mill parts, heavy-duty drives

Heavy Machinery

Construction equipment, transport machinery, agricultural equipment

Custom Industries

Specialized machining for unique applications

Custom Gears

Precision gear manufacturing for demanding applications

Capabilities

- Custom tooth counts, modules, profiles, helix angles per drawings

- High-strength and alloy steels with heat treatment

- Equipment: Haas VF-5 CNC, DMG MORI CTX 510 turning centers

- Gear milling and grinding machines

- Geometry/profile inspection via Zeiss Contura

Applications

- Hydraulic drives and reducers

- Lifting and transport machinery

- Industrial and mobile equipment reducers

- Energy sector drives

- Heavy machinery

- Mining and metallurgy equipment

Materials

Wide range of materials for various applications

Material Types

- Carbon and alloy steels (EN, DIN, AISI, ASTM)

- Stainless steels (EN 1.4301/304, 1.4404/316)

- Aluminum alloys (6xxx, 7xxx series)

- Titanium alloys (EN standards)

- Copper and bronze alloys

Heat Treatment & Surface

- Quenching and tempering

- Normalization

- Nitriding

- Carburizing

- Incoming material inspections

- Certificate verification

Quality Assurance

Comprehensive quality control at every stage

Inspection Equipment

- Zeiss Contura CMM for geometry validation

- Gear measurement tools and profilometers

- Laser trackers and 3D scanners

- Manual inspection tools for parts up to 16m long

Standards & Certifications

- EN ISO 2768 general tolerances

- DIN ISO 286-1 fits and tolerances

- ISO 1328 gear accuracy

- ISO 9001:2015 quality management

- Customer-specific specifications

Zeiss Contura CMM

Quality Inspection

Measurement Process

Ready to Start Your Project?

Whether you need prototype support or full-scale production, we offer fast lead times, expert engineering, and reliable results.

Get In Touch