Hydraulic Cylinders

Design and Production for All Tasks and Operating Conditions

Our company specializes in the production of highly loaded, non-standard and precision hydraulic cylinders designed for the most demanding operating conditions. From compact cylinders for mobile equipment to telescopic systems operating under 500+bar pressure, we develop custom solutions to meet any customer's requirements.

Why Choose HydroForce?

Leading expertise in hydraulic cylinder design and manufacturing

- Full-cycle production: design, CNC machining, assembly, testing, and finishing — all under one roof

- From simple standard cylinders to complex telescopic systems and cylinders with progressive environments

- Expert engineering support at every stage of the project with advanced CAD/CAM systems

- Consistent quality and full technical documentation compliant with ISO / DIN / DNV / ABS / API

- Custom solutions for the most demanding operating conditions and specifications

- 30+ years of experience serving industries worldwide

Technical Capabilities

Advanced manufacturing solutions for every hydraulic challenge

Parameters

- Bore / Rod diameter: up to 1000 mm

- Total cylinder length: up to 16000 mm

- Number of telescopic stages: up to 9

- Working pressures: 500 bar and above

- Operating temperature: from -50°C to +200°C

- Rod coatings: Chrome plating (hard, triplex), Titanium Nitride (TiN), Ceramics

- Materials: Carbon steel, stainless steel, titanium, bronze, exotic alloys

- Sealing systems: Parker, Hallite, Merkel, custom solutions

- Sensors: Position, pressure, temperature and other

- Protocols: CANopen, IO-link, analog signals

Capabilities

- Telescopic cylinders for lifters and mining trucks

- Plunger-type cylinders with precision sealing and piston feedback

- Synchronized multi-point lifting systems for large structures

- Cylinders with integrated sensors for stroke, pressure, and temperature

- Twin and cascade cylinders for confined space installations

- Marine-grade cylinders with OFFSHORE, corrosion and DNV/ABS certification

- Position, pressure, temperature and other sensors integration

- CANopen, IO-Link, analog signals compatibility

Custom Hydraulic Cylinders

We specialize in challenges that standard solutions can't meet. Our experience includes:

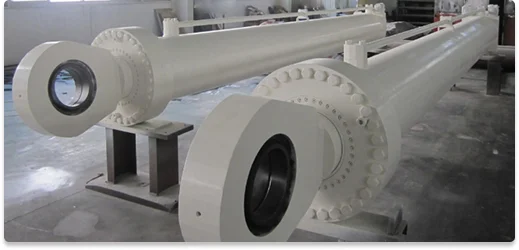

Heavy-Duty Hydraulic Cylinders

Final stage production - after testing and ready for shipment

Ready for Shipment

Custom Solutions

Industrial Applications

Quality Testing

Applications

Precision hydraulic solutions across diverse industrial sectors

Mechanical Engineering

Presses, manipulators, automation systems

Construction

Telescopic lift cylinders, cranes, dump trucks

Military and Aerospace

High-reliability specialized hydraulic cylinders

Mining and Metallurgy

Blast furnaces, manipulators, heavy equipment

Shipbuilding & Offshore

Steering mechanisms, hatches, anchor cylinders

Energy Sector

Synchronized multi-point cylinders, damper cylinders

Project Development Stages

- Task analysis and technical specification (RFQ/TOR)

- Design and modeling including FEA simulation

- Manufacturing on high-precision equipment (DMG MORI, Haas)

- Assembly, sealing, and dimensional inspection

- Testing for pressure, leakage, and fatigue

- Shipment with documentation, packaging, and certifications

Quality Assurance & Testing

- Every cylinder undergoes 100% final testing

- Load testing at working and overpressures

- Dimensional and tolerance inspection

- Electronic functionality testing (if applicable)

- Engineering drawings and material certificates

- Strength calculations and test protocols

Ready to Order Custom Hydraulic Cylinders?

Contact our engineering team for technical consultation and custom manufacturing quote

Request Quote