High-Pressure Die Casting (HPDC)

Precision, Efficiency, and Exceptional Surface Quality

Looking for high-volume production of complex aluminum parts with superior dimensional accuracy? Our High-Pressure Die Casting (HPDC) technology delivers exceptional results for demanding applications.

HPDC Advantages

Why high-pressure die casting is the optimal choice for precision aluminum parts

Dimensional Accuracy

- Tolerances: ±0.1-0.3mm achievable

- Surface finish: Ra 1.6-6.3 μm

- Minimal post-machining required

- Consistent repeatability across production runs

High Production Efficiency

- Fast cycle times (30 seconds to 2 minutes)

- High-volume production capability

- Automated processes for consistency

- Reduced labor costs

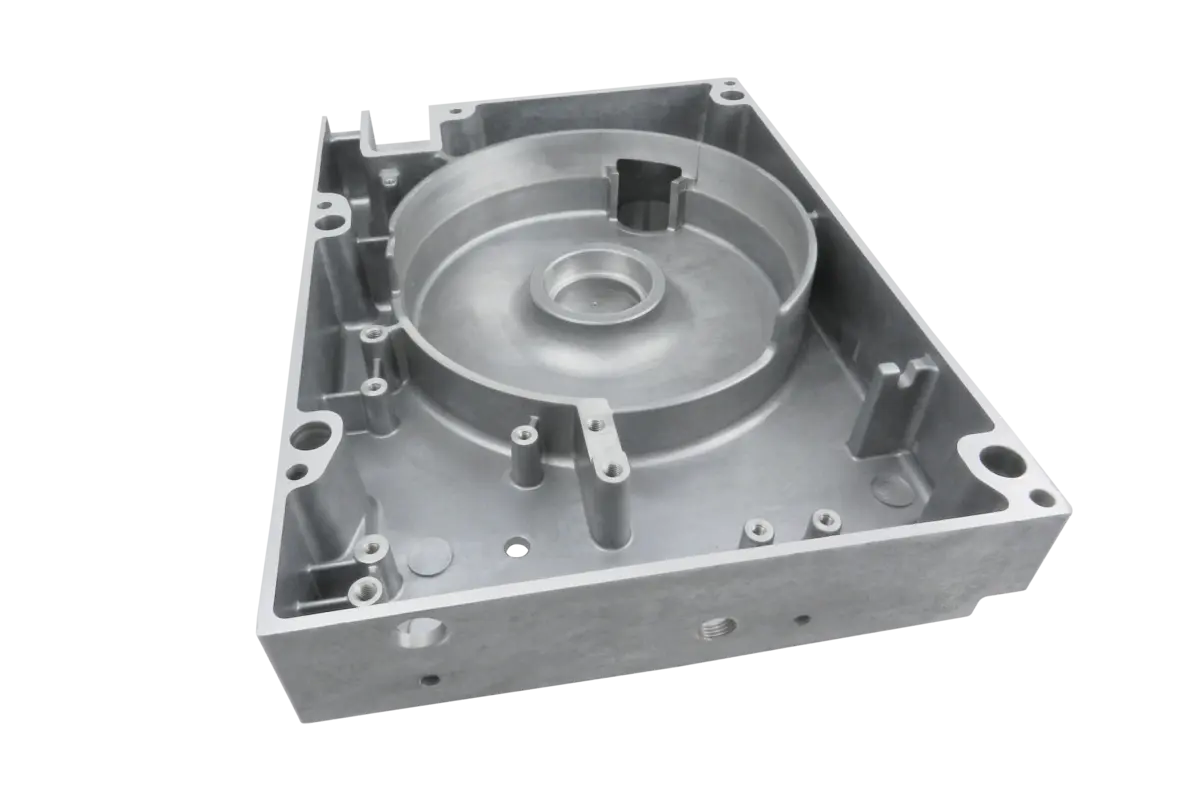

Complex Geometries

- Thin-wall sections (0.5-1.5mm)

- Complex internal features and cavities

- Integrated design features

- Near-net-shape manufacturing

Material Properties

- Excellent strength-to-weight ratio

- Superior mechanical properties

- Corrosion resistance capabilities

- Thermal conductivity for heat dissipation

Cost Effectiveness

- Lower per-unit costs for high volumes

- Reduced material waste

- Minimal finishing operations

- Faster time-to-market

Versatile Applications

- Automotive components

- Electronic housings

- Industrial machinery parts

- Aerospace and defense applications

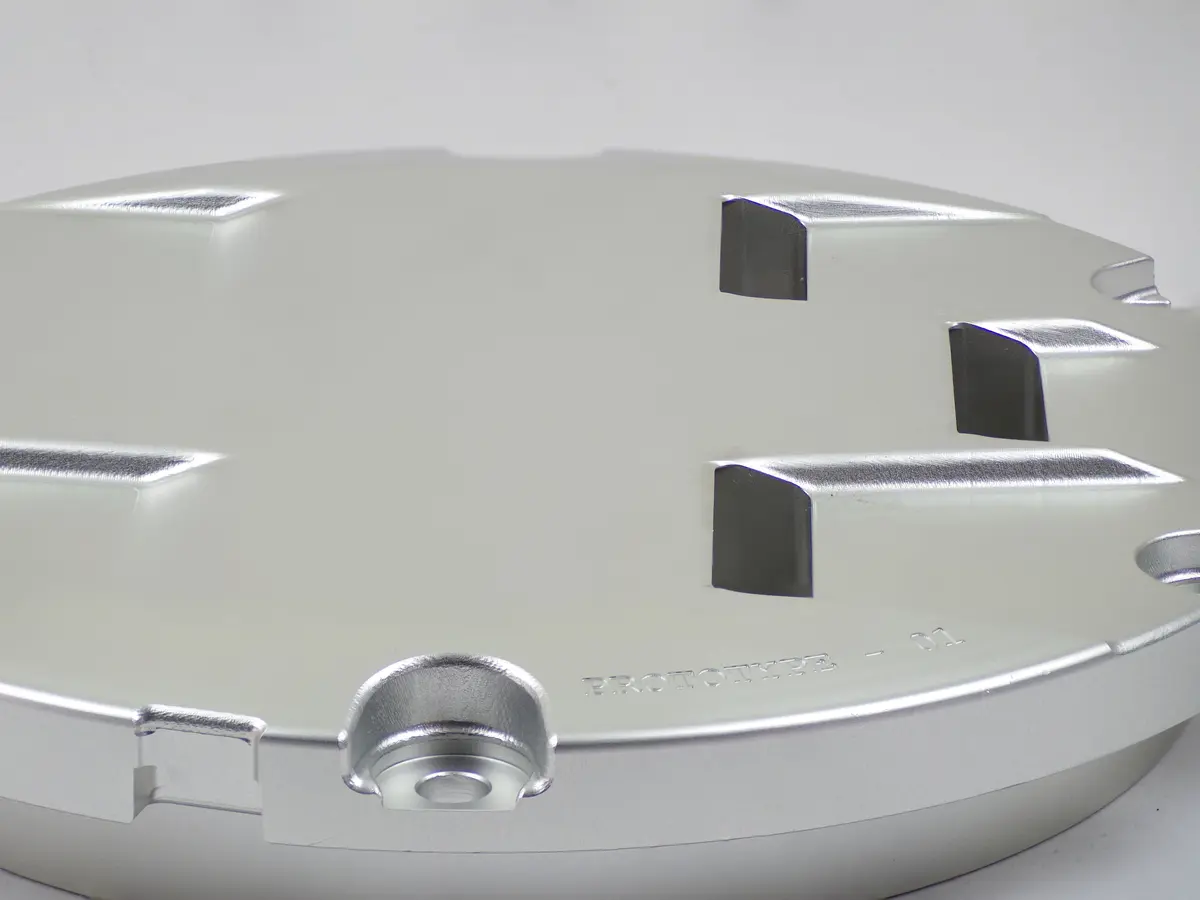

Die Cast Products

Precision aluminum components for various industries

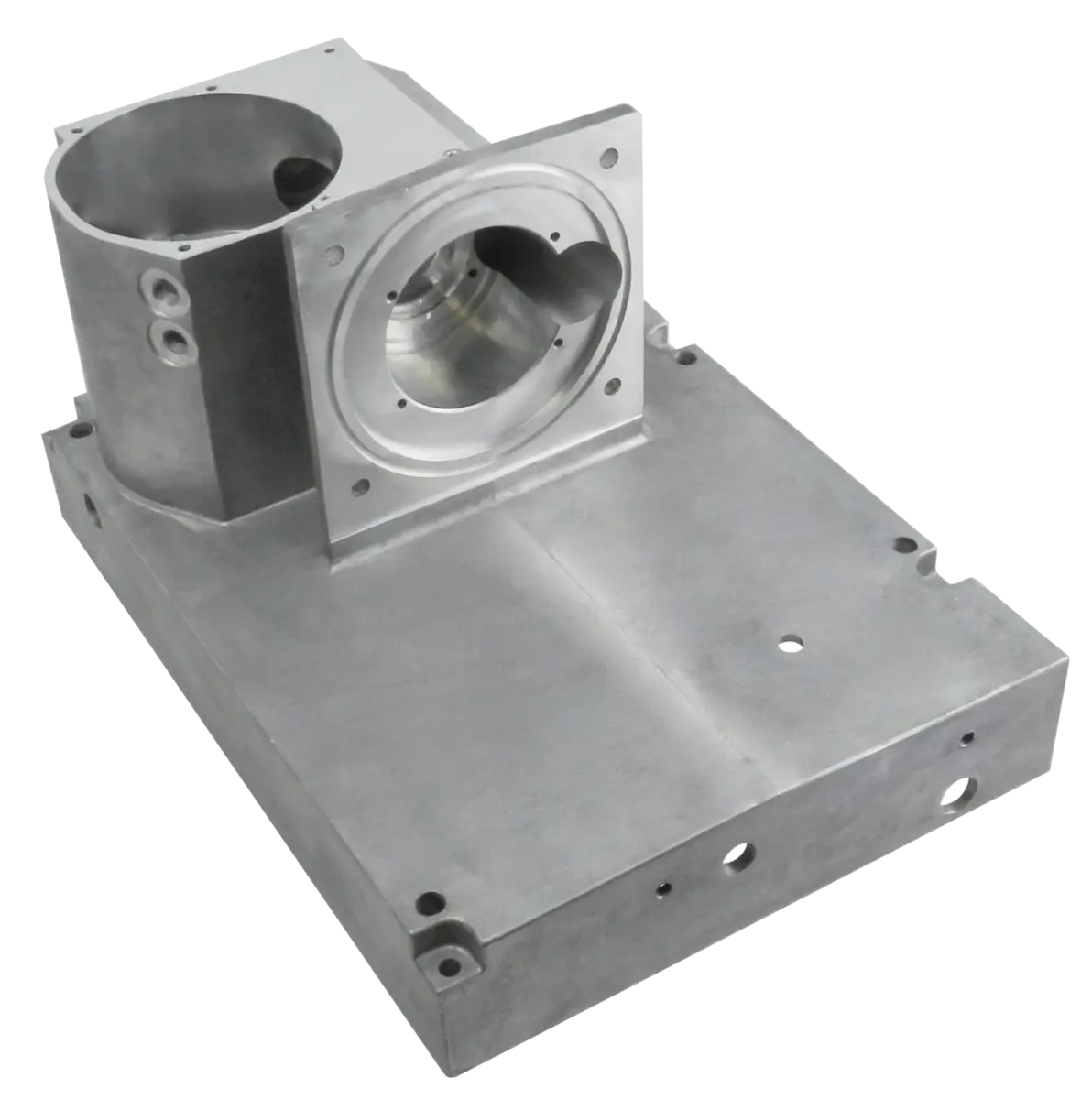

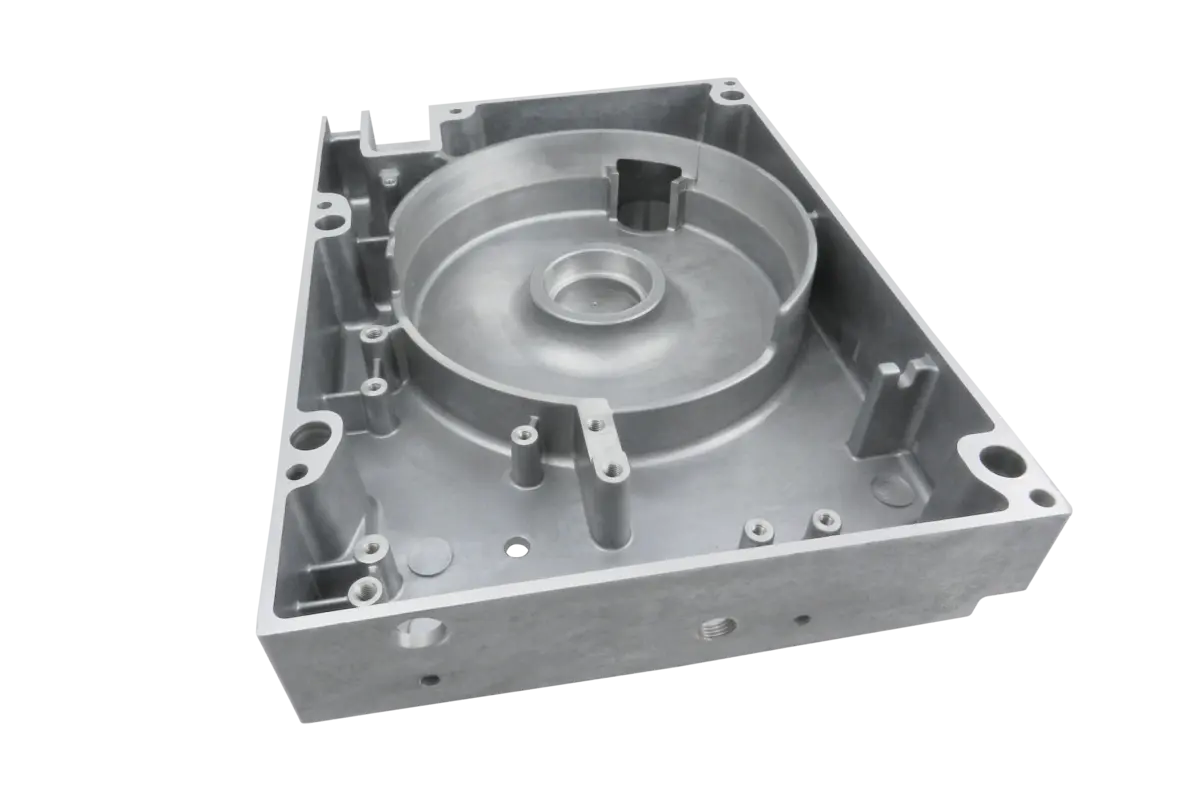

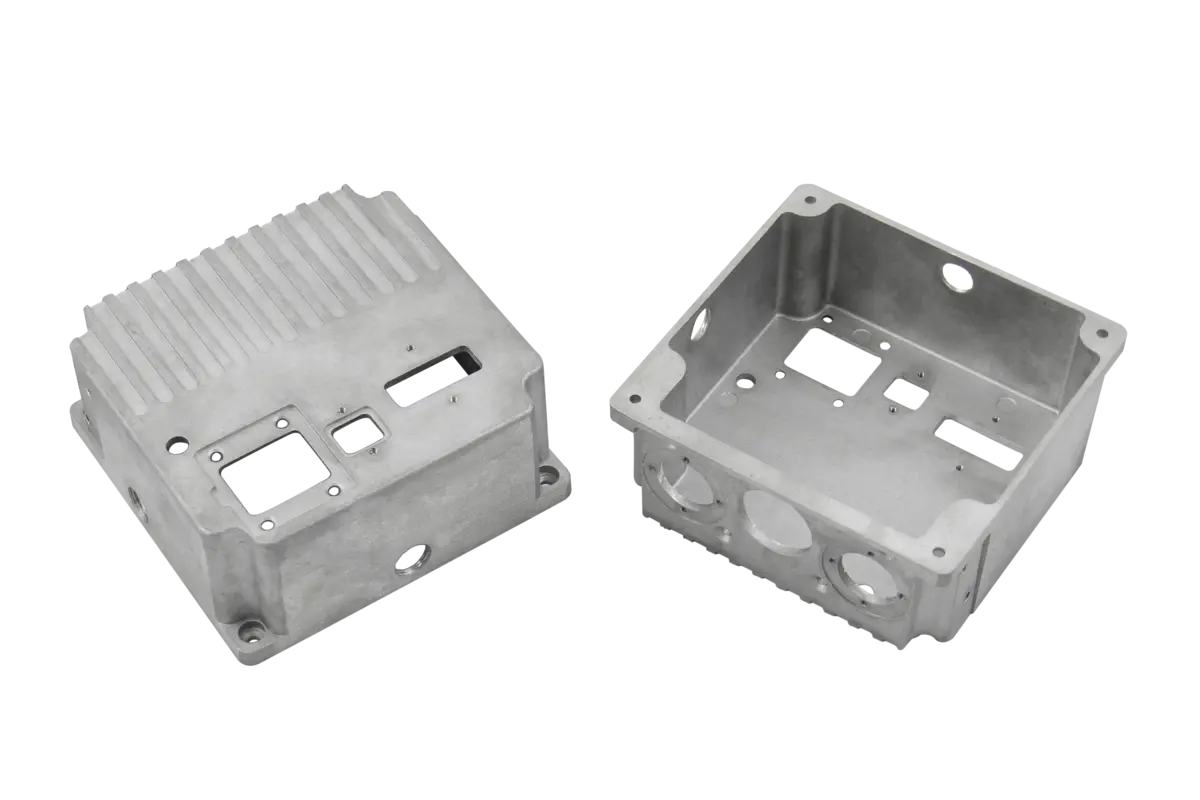

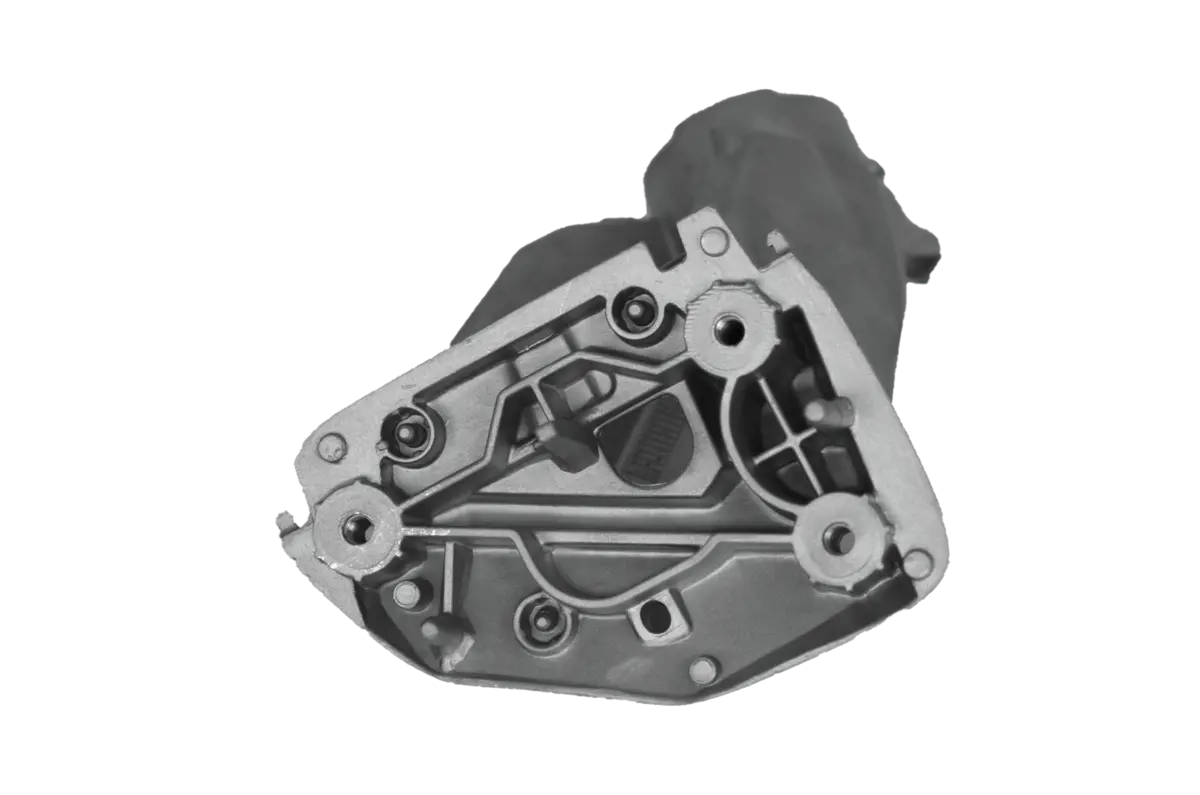

High-Pressure Die Cast Part

Aluminum Die Casting

Precision Die Cast Component

Complex Die Cast Part

Die Cast Component

Precision Part

Complex Geometry

Finished Product

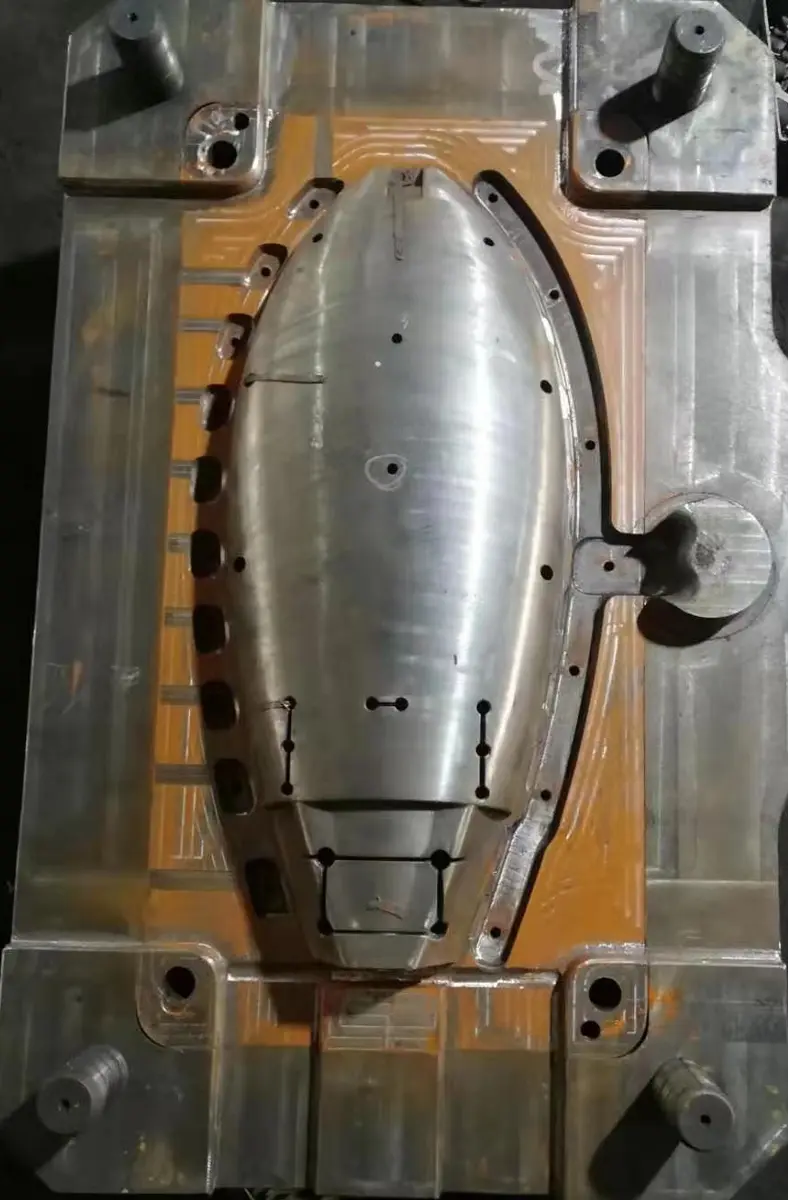

Tooling & Mold Design

Advanced manufacturing capabilities for optimal results

Advanced Manufacturing Capabilities

- State-of-the-art CAD/CAM design for optimal mold geometry

- Precision CNC machining centers

- Premium grade tool steels (H13, P20)

- Advanced cooling/heating systems

- Carefully designed ejection systems

- Comprehensive testing and validation

Mold Design

Tooling

CAD Design

Surface Finishing & Post-Processing

Complete range of finishing services for production-ready parts

Trimming & Deburring

Precision removal of excess material and flash

CNC Machining

Secondary operations for critical dimensions

Surface Treatments

Anodizing, powder coating, painting

Heat Treatment

T6 heat treatment for improved mechanical properties

Assembly Services

Integration of inserts and fasteners

Quality Inspection

Dimensional and surface verification

Quality Control

Comprehensive quality assurance at every production stage

Quality Assurance Standards

- CMM (Coordinate Measuring Machine) dimensional inspection

- Surface roughness measurement and visual inspection

- Mechanical property and material composition testing

- X-ray inspection for internal defects

- Statistical Process Control with real-time monitoring

- ISO 9001 quality management system implementation

Zeiss Precision Measurement Systems

Quality Inspection Process

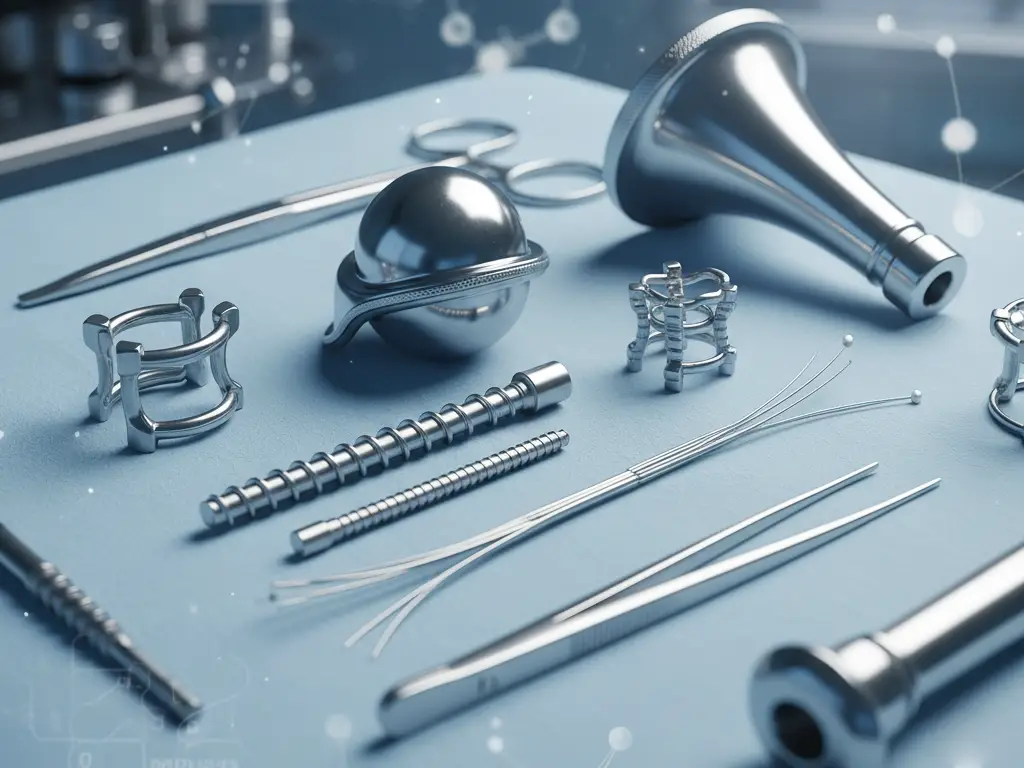

Who We Serve?

HPDC solutions across diverse industrial sectors

Automotive

Engine components, transmission housings

Electronics

Heat sinks, enclosures, connectors

Aerospace

Lightweight structural components

Industrial Equipment

Machinery housings, brackets

Consumer Goods

Appliance components, hardware

Medical Devices

Equipment housings, precision parts

Why Choose HydroForce?

Your trusted partner for high-pressure die casting

- 20+ years of experience in die casting and precision manufacturing

- State-of-the-art production facilities with advanced automation

- Comprehensive in-house capabilities from tooling to finishing

- Flexible production volumes from prototypes to high-volume series

- Full quality assurance and ISO 9001 certification

- Expert engineering support and design optimization services

- Competitive pricing and reliable delivery schedules

Ready to Start Your Project?

Contact us for a consultation and quote. Tell us about your requirements — we'll provide the most efficient HPDC solution.

Get Started